Fußschutz

Sicherheitsschuhe sind vom Unternehmer zur Verfügung zu stellen und von den Beschäftigten zu

benutzen, wenn mit Fußverletzungen durch Stoßen, Einklemmen, herabfallende oder herunterrollende

Gegenstände, durch Hineintreten in spitze oder scharfe Gegenstände oder durch heiße Stoffe, heiße

oder ätzende Flüssigkeiten zu rechnen ist.

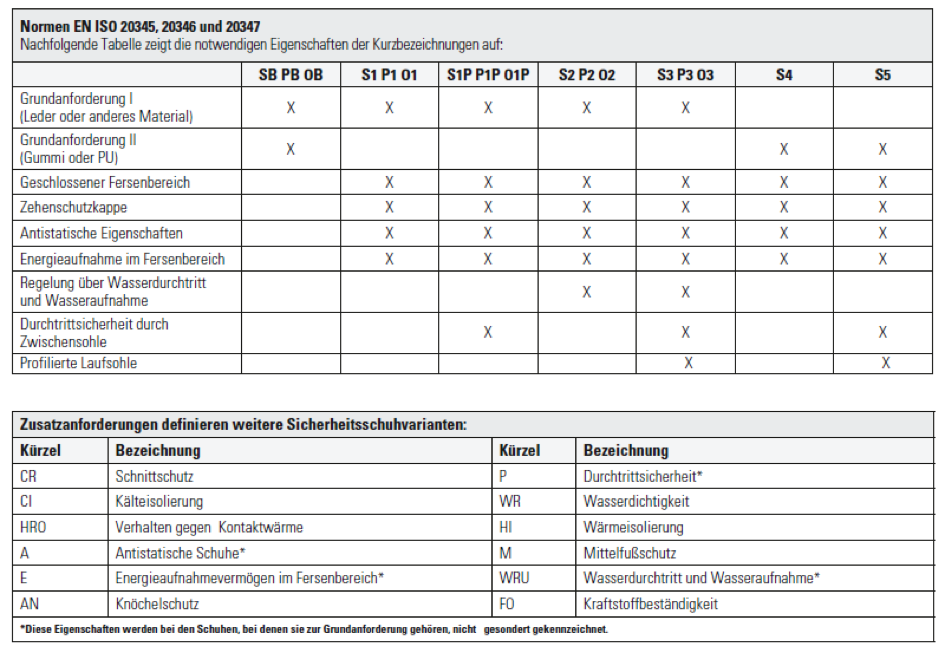

Die Europäischen Normen (EN) für Schuhe im gewerblichen Gebrauch

EN ISO 20344:2011 – Vorschriften zur Prüfung (für Hersteller und Prüfinstitute notwendig)

EN ISO 20345:2011 – Anforderungen an Sicherheitsschuhe (Kennzeichnung S) Zehenschutzkappe

belastbar bis 200 Joule

EN ISO 20346:2011 – Anforderung an Schutzschuhe (Kennzeichnung P) Zehenschutzkappe belastbar bis 100 Joule

EN ISO 20347:2011 – Anforderungen an Berufsschuhe (Kennzeichnung O) Keine Zehenschutzkappe eingebaut

Gültige Normen für Schweißer- und Gießerstiefel, Forststiefel, Feuerwehrstiefel und ESD

Schuhe

EN ISO 20349-2:2017 – Anforderungen an Schweißer- und Gießerstiefel

EN ISO 17249:2014 – Anforderungen an Forststiefel

DIN EN 15090:2012 – Anforderungen für Feuerwehrstiefel

EN ISO 61340 – Anforderungen für ESD Schuhe

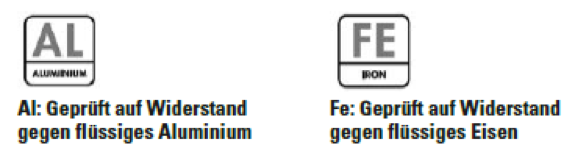

EN ISO 20349-2:2017: Norm für Gießerstiefel

Norm für Schuhe zum Schutz gegen thermische Risiken und Spritzer geschmolzenen Metalls. Die Norm stellt erweiterte Anforderungen an die Ausstattung von Gießer- und Schweißerstiefeln. Die Schuhe müssen verschiedene Prüfverfahren im Zusammenhang mit extremer Wärmeeinwirkung und Kontakteinwirkung mit geschmolzenem Metall standhalten. Dies gilt besonders für die Beschaffenheit des Obermaterials sowie für die Hitzebeständigkeit des Sohlenkomplexes.

EN ISO 17249-2014: Norm für Schnittschutzstiefel

Norm für Sicherheitsschuhe mit Schutz gegen Schnitte durch handgeführte Kettensägen. 100%iger Schutz kann durch PSA nicht gewährleistet werden.

Die verschiedenen Schuhformen. Die Form beschreibt die Höhe des Schuhschaftes (Form A-D):

Form A: Halbschuh

Form B: Knöchelhoher Schuh

Form C: Stiefel halbhoch

Form D: Stiefel hoch

DGUV 112-191 – Orthopädische Schuheinlagen

Vorgehensweise für die Herstellung und Zurichtung von orthopädischen Sicherheits- und

Berufsschuhen

Der Schuhhersteller fertigt für das Baumusterprüfverfahren Prototypen orthopädischen Fußschutzes.

Diese Schuhe werden mit allen erforderlichen Unterlagen (z.B. technische Dokumentation,

Materialbeschreibung und Herstellerinformation) von einer akkreditierten und notifizierten Prüfstelle

auf Übereinstimmung mit der 8. Verordnung zum Geräte und Produktsicherheitsgesetz (8. GPSGV)

geprüft (Baumusterprüfung).

Die Fertigungsanweisung ist zwingend einzuhalten; sie enthält neben verfahrenstechnischen

Anweisungen auch Materialvorgaben für die Schuhherstellung.

Nach Erteilung der EG-Baumusterprüfbescheinigung durch eine notifizierte Stelle kann mit der Erlaubnis des Schuhherstellers jeder einschlägig orthopädisch qualifizierte Hersteller den orthopädischen Fußschutz individuell herstellen oder zurichten sofern er entsprechend der Fertigungsanweisung arbeitet. Mit der CE-Kennzeichnung erklärt er abschließend eigenverantwortlich, dass der Schuh auf der Grundlage des Prüfmusters gefertigt wurde. Der Schuh wird darüber hinaus entsprechend der Norm gekennzeichnet und die Herstellerinformation wird beigefügt.

Artikel mit dieser Zusatzprüfung tragen im Katalog den Hinweis auf die DGUV 112-191.