Atemschutz

Werden bei Tätigkeiten Stäube, Gase oder Dämpfe frei und ist keine effektive Absaugung dieser Gefahrstoffe vorhanden, muss Atemschutz getragen werden. Für Schadstoffe sind Grenzwerte festgelegt, die am Arbeitsplatz nicht überschritten werden dürfen (MAK – Maximale Arbeitsplatzkonzentration, TRK = Technische Richtkonzentration).

Ist die Konzentration höher, muss man sich gegen sie schützen. Gefährdungsbeurteilungen sind gemäß DGUV Regel 112-190 durchzuführen.

Vorschriften und Normen

Nach VGB1 § 4 (2) hat der Unternehmer Atemschutz zur Verfügung zu stellen, wenn Versicherte gesundheitsschädlichen, insbesondere giftigen, ätzenden oder reizenden Gasen, Dämpfen, Nebeln oder Stäuben ausgesetzt sein können.

Der Bereich Atemschutz ist der Kategorie III (tödliche Gefahren oder irreversible Schäden) zugeordnet.

Es gibt folgende Atemschutzprodukte:

1. Partikelatemschutz:

Partikelatemschutz (EN149) bestehen zum größten Teil aus dem Filtermaterial selbst und bieten Schutz vor Staub, Rauch, Mikroorganismen und Nebel. Aus hygienischen Gründen sind Sie meist nur den einmaligen Gebrauch ausgelegt. Aktivkohlezusätze können zusätzlich gegen belästigende Gerüche hilfreich sein, schützen jedoch nicht vor schädigenden Gasen und Dämpfen.

Klasseneinteilung der Partikelfilter (EN149:2001 + A1:2009):

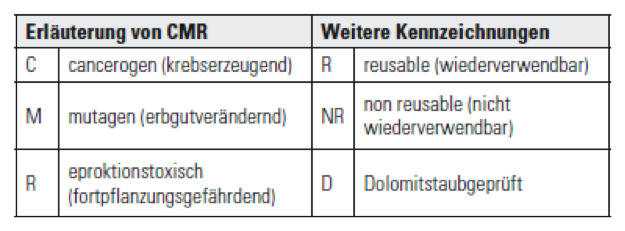

- Partikelfilter Schutzstufe P1 bzw. FFP1: gegen ungiftige Stäube und Aerosole auf Wasser- und Ölbasis. Nicht gegen CMR-Stoffe, radioaktive Partikel, Enzyme, sowie luftgetragene biologische Arbeitsstoffe der Risikogruppen 2 und 3. Bis zum 4-fachen des erlaubten Grenzwertes einsetzbar (AGW – allgemeiner Grenzwert).

- Partikelfilter Schutzstufe P2 bzw. FFP2 : gegen ungiftige Stäube und Aerosole auf Wasser- und Ölbasis. Zusätzlich gegen CMR-Stoffe und luftgetragene biologische Arbeitsstoffe der Risikogruppen 2 und 3 wenn eine Gefährdungsbeurteilung vorliegt. Bis zum 10-fachen des Grenzwertes erlaubt.

- Partikelfilter Schutzstufe P3 bzw. FFP3: gegen gesundheitsschädliche Stäube und Aerosole auf Wasser- und Ölbasis. Gegen CMR-Stoffe, radioaktive Partikel, Enzyme, sowie luftgetragene biologische Arbeitsstoffe der Risikogruppen 2 und 3. Bis zum 30-fachen des Grenzwertes einsetzbar.

Der neue Allgemeine Staubgrenzwert: 1,25 mg/m³

Die Technische Regel für Gefahrstoffe (TRGS 900) besagt, dass Belastungen am Arbeitsplatz durch Staub auf mögliche Gefährdungen hin bewertet werden müssen. Es gilt der neue Grenzwert von 1,25mg/ m3 (alveolengängiger Staub). Die Übergangsfrist für die Umsetzung der neuen Regel ist der 31.12.2018. Staubbelastete Arbeitsplatze müssen nach der neuen TRGS900 hin überprüft werden und erfordern ggf. höhere Schutzmaßnahmen als bisher.

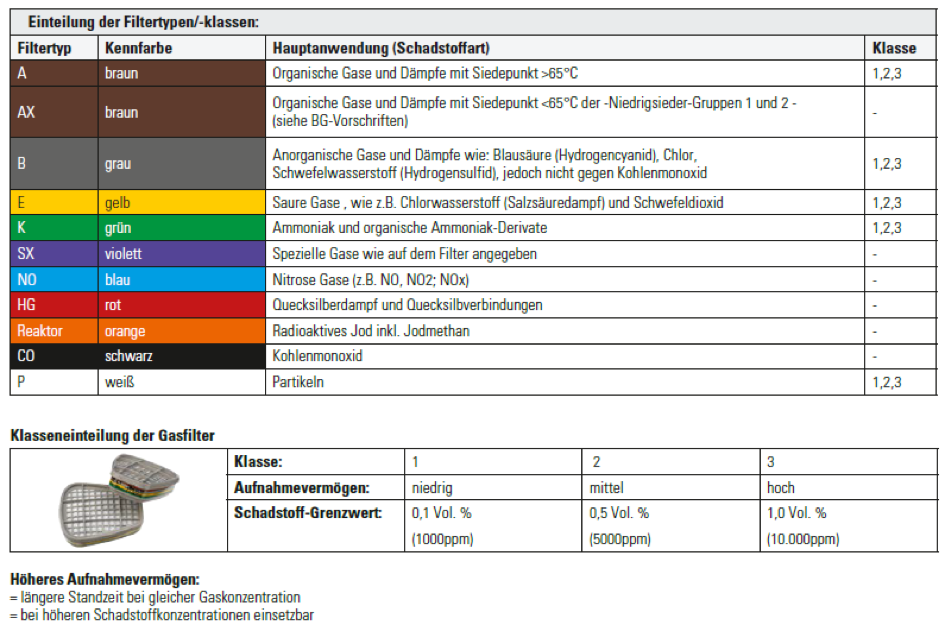

2. Gase-/Dämpfe-Atemschutz

bietet Schutz vor Gasen, Dämpfen und/oder Partikeln wobei die entsprechenden Filter in Gasfilter, Kombinationsfilter, Mehrbereichsfilter und Mehrbereichs-Kombinationsfilter unterteilt werden.

Die Filterart bestimmt die Schutzwirkung und den Schutzfaktor. Zum Schutz gegen Dampfe und Gase oder gegen Partikel oder Kombinationen davon.

- Halbmasken (EN 140) umschließen den Nasen,- Mund,- und Kinnbereich

- Vollmasken (EN 136) bedecken das gesamte Gesicht und bieten somit einen zusätzlichen Augenschutz

3. Gebläse und Druckluftatemschutz

Zum Schutz vor extremer Schadstoffbelastung

Gebläsefiltergeräte: Die Umgebungsluft wird angesaugt und durch die auswechselbaren Filter gereinigte Luft über eine Haube oder Maske dem Anwender zugeführt. Erhöhter Tragekomfort.

Je nach Schadstoffen sind geeignete Atemfilter auszuwählen!

Die Standzeit von Filtern ist von verschiedenen Einflussfaktoren (z.B. Schadstoffart, Umgebungstemperatur, Schadstoffkonzentration, Luftfeuchtigkeit) abhängig.

Das Verfallsdatum ist auf den einzelnen Filtern vermerkt. Geöffnete Gas- und Kombinations-filter sind spätestens 6 Monate nach dem Öffnen zu ersetzen. Die Lagerzeit von Partikeln liegt bei ca. 4 Jahren. Die Gebrauchsdauer von Filtern ist beschränkt und hängt von der Filterklasse, den Umgebungsbedingungen sowie der Atemleistung des Benutzers ab. Gasfilter sind dann auszutauschen, wenn der Geruch bzw. Geschmack des Gases spürbar wird. Partikelfilter und partikelfiltrierende Masken nach einer Schicht bzw. wenn der Atemwiderstand merklich ansteigt.

Bedeutung der EN-Kennzeichnung/Normen

| EN136 | Vollmasken |

| EN140 | Halbmasken |

| EN141 | Gasfilter und Kombinationsfilter |

| EN 143 | Partikelfilter |

| EN 149 | Filtrierende Halbmasken zum Schutz gegen Partikel |

| EN 403 | Filter Fluchtgeräte |

| EN 405 | Filtrierende Halbmasken m. Ventil zum Schutz gegen Gase oder Partikel |

| EN 529 | Atemschutzgeräte-Empfehlung für Auswahl, Einsatz, Pflege und Instandhaltung-Leitfaden |